Understanding Oxy Gas Welding Kits

What is an Oxy Gas Welding Kit?

An oxy gas welding kit is a specialized assembly of tools and equipment designed for welding and cutting metals using a combination of oxygen and flammable gas, typically acetylene. This method, known as oxy-acetylene welding, harnesses high-temperature flames capable of melting metal for effective bonding. It remains a staple in various industries, from metal fabrication to art, due to its versatility and effectiveness.

Components of a Quality Oxy Gas Welding Kit

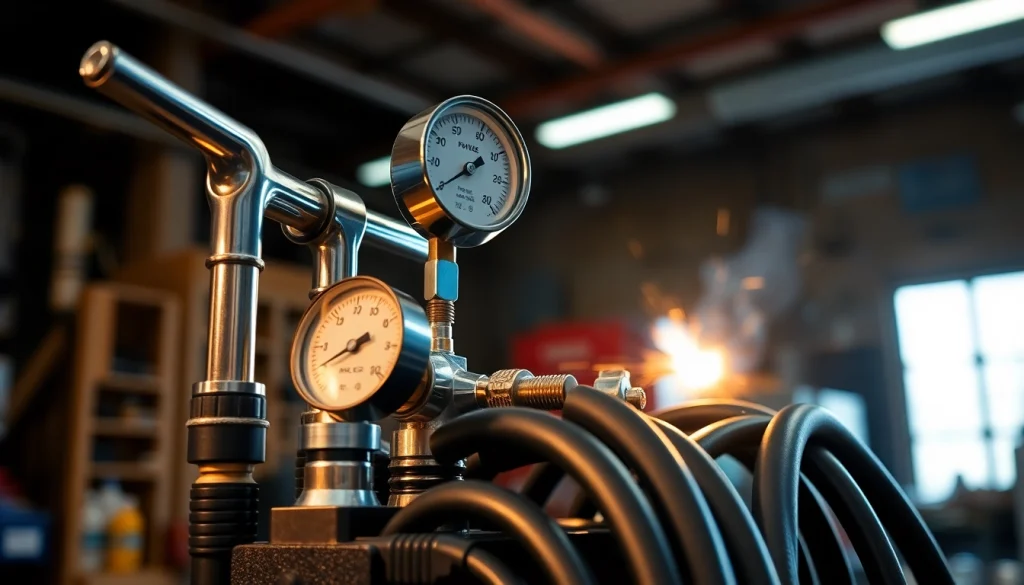

A complete oxy gas welding kit typically includes several essential components:

- Welding Torch: The primary tool used to mix and control the flow of oxygen and gas. It often features interchangeable nozzles and control valves.

- Regulators: Devices that regulate the gas pressure from the tanks to the torch, ensuring a steady flow of gas for consistent welding performance.

- Gas Cylinders: Containers that hold oxygen and acetylene. They are usually made of high-strength steel and come equipped with safety features.

- Hoses: Flexible tubes that transport the gases from the cylinders to the torch. They must be durable and able to withstand high pressure.

- Fittings and Adapters: Components that connect the hoses to the torch and gas cylinders, ensuring a secure and leak-proof connection.

- Safety Gear: Including goggles, gloves, and protective clothing, these items are essential for the welder’s safety during operation.

For an in-depth understanding of the various components of oxy gas welding kits, visit this oxy gas welding kit overview.

Applications of Oxy Gas Welding Kits

Oxy gas welding kits find applications across a wide range of industries. Some of the most common uses include:

- Metal Fabrication: Used extensively in fabricating metal structures like frames, gates, and art installations.

- Automotive Repair: Essential for repairing and modifying vehicles, especially for welding and cutting exhaust systems.

- Pipeline Construction: Utilized in joining and repairing pipelines due to its ability to produce strong, high-quality welds.

- Jewelry Making: Craftspeople employ oxy-acetylene welding for working with small, delicate pieces of metal effectively.

- Arts and Crafts: Artists leverage this technique for creating sculptures or artistic pieces from metals.

Choosing the Right Oxy Gas Welding Kit

Factors to Consider When Selecting

Selecting the right oxy gas welding kit involves several critical factors:

- Type of Welding: Determine the types of metals you will be working with and whether you need a kit specifically for light, medium, or heavy-duty work.

- Portability: If you plan on using the kit at various locations, opt for a lightweight, portable kit that includes a carrying case.

- Safety Features: Look for kits that include safety mechanisms such as flashback arrestors and pressure regulators that prevent gas leaks.

- Brand Reliability: Reputable brands are often more trustworthy in terms of product quality and customer service options.

- Budget: Understand your budget constraints while considering that investing in a slightly more expensive, high-quality kit can save you additional costs on replacements and repairs in the long run.

Common Brands and Their Features

Some notable brands in the oxy gas welding kit domain include Harris, Victor, and Lincoln Electric. These brands are renowned for their quality and reliability:

- Harris: Offers a wide range of oxygen and acetylene torches, known for their precision and durability. Their kits often come with efficient regulators and lightweight hoses.

- Victor: Popular for its professional-grade torch kits that provide excellent flame control and safety features, ensuring a higher quality welding experience.

- Lincoln Electric: Known for both gas and electric welding equipment, their oxy gas welding kits often include added features like robust construction and extended warranties.

User Reviews and Performance Metrics

When evaluating an oxy gas welding kit, user reviews can shed light on real-world performance. Look for reviews that highlight:

- Ease of Setup: Users often comment on how simple the kit is to assemble and the clarity of instructions provided.

- Durability: Kit longevity and ability to withstand heavy usage are significant factors, especially for professionals.

- Flame Control: Many reviews provide insights on how well the torch handles adjustments for different welding tasks.

- After-sales Support: Customer service experiences related to warranty claims or product returns are crucial for potential buyers.

Setting Up Your Oxy Gas Welding Kit

Required Safety Equipment

Safety should always be the top priority when setting up an oxy gas welding kit. Essential safety gear includes:

- Welding Goggles: Protect your eyes from the intense light generated during welding.

- Gloves: Heat-resistant gloves shield your hands from burns and cuts.

- Flame-proof Clothing: Wear long sleeves and pants to protect your skin from sparks and heat.

- Face Shield: Consider a full face shield for additional facial protection.

Step-by-Step Setup Guide

Follow these steps to effectively set up your oxy gas welding kit:

- Check Equipment: Inspect your kit for any missing parts or damage.

- Secure Location: Set up in a well-ventilated area with no flammable materials nearby.

- Assemble Components: Attach the hoses to the gas regulators and connect them to the appropriate gas cylinders.

- Pressure Adjustment: Open the cylinder valves slowly and adjust the pressure using the regulators.

- Check for Leaks: Use a soapy water solution to test for leaks around connections.

- Ignite the Torch: Follow the manufacturer’s instructions for safely igniting the torch.

Troubleshooting Common Setup Issues

During setup, you may encounter various issues, such as:

- Gas Leaks: If you detect a leak, immediately turn off the gas supply and check hose connections.

- Flame Not Igniting: Ensure that you have gas flowing to the torch and that it is ignited in the correct sequence.

- Flame Characteristics: If the flame is not stable, adjust the oxygen and acetylene flow until a neutral flame is achieved.

Using Your Oxy Gas Welding Kit Effectively

Basic Welding Techniques for Beginners

For those new to oxy gas welding, mastering the following techniques is essential:

- Striking the Arc: Practice safely igniting the torch and achieving a stable flame.

- Controlling the Flame: Learn to adjust the mixture of oxygen and acetylene to achieve a neutral flame for welding.

- Welding Joints: Familiarize yourself with techniques for welding various types of joints, such as butt and lap joints.

Advanced Welding Techniques to Master

As you gain proficiency, you may want to explore advanced techniques such as:

- Brazing: Using a filler metal with a lower melting point to join similar or dissimilar metals.

- Heat Treatment: Understanding how different heating processes can change metal properties during welding.

- Welding Thin Materials: Special techniques to prevent warping and maintain integrity in thin materials.

Maintenance Tips for Your Oxy Gas Welding Kit

To ensure optimal performance and longevity of your oxy gas welding kit, consider these maintenance practices:

- Regular Inspection: Periodically check for wear and tear on hoses and connections, replacing any damaged components.

- Proper Storage: Store your equipment in a cool, dry place, away from direct sunlight and extreme temperatures.

- Cleaning: Keep the torch and nozzles clean; use a soft brush to remove debris and buildup.

- Calibration: Occasionally test and calibrate regulators to ensure accurate pressure settings.

The Future of Oxy Gas Welding

Comparing Oxy Gas with Other Welding Methods

In the ever-evolving landscape of welding technologies, oxy gas welding maintains its relevance when compared to other methods such as MIG and TIG welding. While MIG welding is favored for speed and efficiency, particularly in mass production, oxy-acetylene welding is preferred for repair work and thin materials due to its flexibility and ease of use. Each method has its advantages, making them suitable for specific applications.

Emerging Technologies in Welding

New welding technologies such as laser welding and plasma cutting are gaining popularity for particular industrial applications. These methods offer precision and reduced heat-affected zones, but they typically require more investment and specialized training. Oxy gas welding still plays an essential role in industries where machinery repair and artisan metalworking are prevalent.

Maintaining Relevance in Industry Trends

For professionals and hobbyists alike, staying current with the trends in welding technology is crucial. Education, continuous practice, and investing in advanced training will help welders adapt to new technologies while still utilizing traditional methods like oxy gas welding. Networking with industry professionals and participating in workshops can enhance skills and knowledge, ensuring ongoing relevance in the field.