Introduction to IR Paint Curing Lamps

In the landscape of modern manufacturing and industrial processes, speed and efficiency reign supreme. Whether it’s automotive painting, product finishing in manufacturing, or drying ink in printing, the need for swift and effective solutions cannot be overstated. Enter ir paint curing lamps, a transformative technology that is reshaping how heat is applied in various sectors. These lamps utilize infrared technology to expedite the curing and drying processes, delivering remarkable energy efficiency and operational advantages.

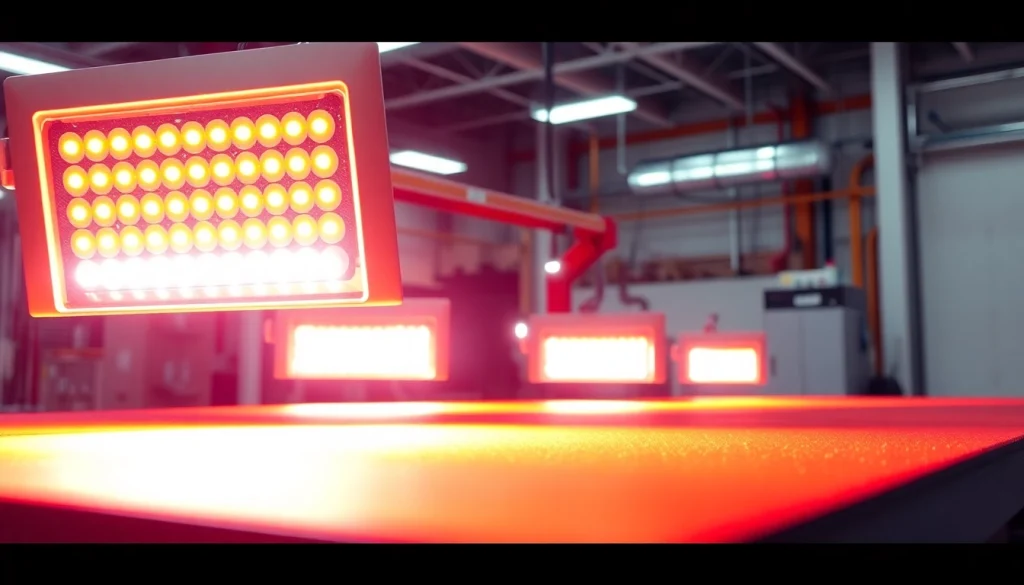

What are IR Paint Curing Lamps?

IR paint curing lamps are specialized devices designed to emit infrared radiation, facilitating the rapid curing of paints, coatings, and other materials. Unlike traditional heating methods that elevate the air temperature in a chamber, these lamps direct radiant energy precisely to the surfaces being treated. This focused approach not only speeds up the curing time significantly but also ensures even heat distribution, minimizing defects that can arise from irregular drying.

Applications in Various Industries

The applications of IR paint curing lamps span multiple industries, making them a versatile tool in modern production environments. In the automotive sector, these lamps are employed to cure paints and coatings on vehicle bodies, enhancing both the efficiency of the painting process and the quality of the finish. In the printing industry, ink-drying lamps are critical for ensuring that printed materials are cured quickly and effectively, thus preventing smudging and ensuring high-quality results. Additionally, manufacturing facilities utilize these lamps for curing adhesives and coatings on a range of products, from electronics to furniture.

Advantages Over Traditional Heating Methods

The advantages of using IR paint curing lamps over traditional heating methods are manifold. First and foremost, they provide a significant boost in energy efficiency, achieving energy conversion rates of up to 96%. This high level of efficiency translates into lower operational costs, enabling businesses to save between 20% to 50% on fuel expenses compared to conventional systems. Moreover, the targeted heating capability of IR lamps reduces the likelihood of overheating surrounding areas, thereby minimizing potential damage and ensuring a consistent, high-quality finish on the products being treated.

Understanding Infrared Technology

How IR Paint Curing Lamps Work

Infrared paint curing lamps function by emitting infrared radiation, which is a form of electromagnetic energy. This radiation is absorbed by the surface of the material being cured, causing the molecules in the paint or coating to vibrate and thus generating heat. The heat promotes quicker chemical reactions and results in faster drying and curing times, which are critical in high-volume production settings.

Types of Infrared Waves Used

Infrared radiation is categorized into three primary types: short-wave, medium-wave, and long-wave. Short-wave infrared radiation operates at higher temperatures and is often used in quick-drying applications, making it ideal for processes requiring immediate results. Medium-wave infrared radiation strikes a balance between drying speed and even heat distribution, whereas long-wave infrared radiation is generally slower and is used for applications that benefit from lower temperatures over a longer period. Understanding the differences among these wave types is crucial for selecting the right IR paint curing lamps for specific applications.

Benefits of Advanced IR Technology

Advanced IR technology brings numerous benefits to the table. The enhanced heating efficiency is one of the most notable advantages, allowing for quick heat-up times and reduced waiting periods in production lines. Furthermore, the precision of infrared technology means that manufacturers can achieve uniform heating across varying surfaces, which is crucial for maintaining quality control in production. The compact nature of IR lamps also allows for flexible installation options, accommodating different production layouts.

Applications and Use Cases

Automotive Drying and Heating Solutions

In the automotive industry, effective paint curing is vital to ensuring the durability and aesthetics of vehicle finishes. IR paint curing lamps are an integral part of modern paint shops, where they help rapidly cure base coats, clear coats, and other finishes. By accelerating the drying process, these lamps not only enhance production efficiency but also improve the overall quality of the finish, reducing the risk of defects and ensuring that vehicles meet stringent quality standards.

Ink-Drying for Printing Businesses

Printing businesses, particularly those focusing on high-volume production, rely heavily on rapid ink drying solutions. IR lamps play a critical role in the printing process by curing inks almost instantly, thus allowing for faster production times and lower costs. The capability to cure inks quickly also reduces the chance of smudging and ensures that printed materials can be handled immediately, streamlining the workflow in printing establishments.

Industrial Manufacturing Heating Solutions

Beyond automotive and printing, IR paint curing lamps find applications in various sectors, including electronics and furniture manufacturing. In these industries, they are used for curing adhesives, lacquers, and protective coatings applied to products. The efficiency and effectiveness of IR technology greatly enhance productivity, allowing manufacturers to meet high demand while maintaining quality standards.

Choosing the Right IR Paint Curing Lamps

Factors to Consider When Selecting a Lamp

Selecting the appropriate IR paint curing lamp requires careful consideration of several factors. First, businesses should evaluate the specific requirements of their applications, including the type of materials being cured and the desired speed of the curing process. Furthermore, the wavelength of the infrared rays emitted by the lamp should be compatible with the curing needs of the materials used. Companies should also consider the physical space available for installation and the overall energy consumption of the lamps to ensure long-term cost-effectiveness.

Energy Efficiency and Cost Benefits

The investment in IR paint curing lamps can yield substantial long-term savings due to their remarkable energy efficiency. By providing up to 96% energy conversion, these systems drastically reduce energy costs compared to traditional heating methods. Additionally, the speed of curing leads to shorter production cycles, which can significantly enhance throughput and profitability for manufacturing operations.

Customization Options Available

Many manufacturers, including Huai’an Yinfrared Heating Technology, offer customizable options for IR paint curing lamps. Customizations may include adjustments to wavelength, lamp size, and mounting configurations to suit specific production environments. This flexibility allows businesses to tailor their heating solutions to meet precise operational requirements, which can be a significant advantage in achieving optimal efficiency and quality outcomes.

Future Trends in Infrared Heating Technology

Innovations in IR Paint Curing Lamps

The landscape of infrared heating technology is constantly evolving, with ongoing innovations aimed at improving energy efficiency, performance, and application versatility. Future trends include enhanced digital controls that allow for precise temperature management and real-time monitoring of curing processes. Advances in materials and design are also expected to further increase the efficiency and longevity of IR curing lamps, making them an indispensable tool across various industries.

Sustainability and Environmental Impact

Sustainability is becoming an increasingly significant factor in industrial production methods. IR paint curing lamps contribute to environmental sustainability by requiring less energy and reducing emissions compared to traditional heating methods. As businesses strive to enhance their green credentials, the adoption of energy-efficient technologies like IR curing lamps will become more prevalent.

The Future of Heating Solutions

The future of heating solutions in the industrial sector will likely be defined by a shift towards more integrated and sustainable technologies. With a growing emphasis on energy conservation and waste reduction, IR heating technology stands at the forefront of this transformation. As manufacturers continue to innovate and adopt cutting-edge technologies, the role of IR paint curing lamps will only expand, cementing their place as a vital component of modern industrial processes.